The space industry is full of excitement about how to do this SpaceX Starship, Blue Origin New Glenn and other heavy missiles will change almost everything. One possible outcome is that spacecraft will become larger, much larger, as engineers work outside the constraints of lower mass requirements.

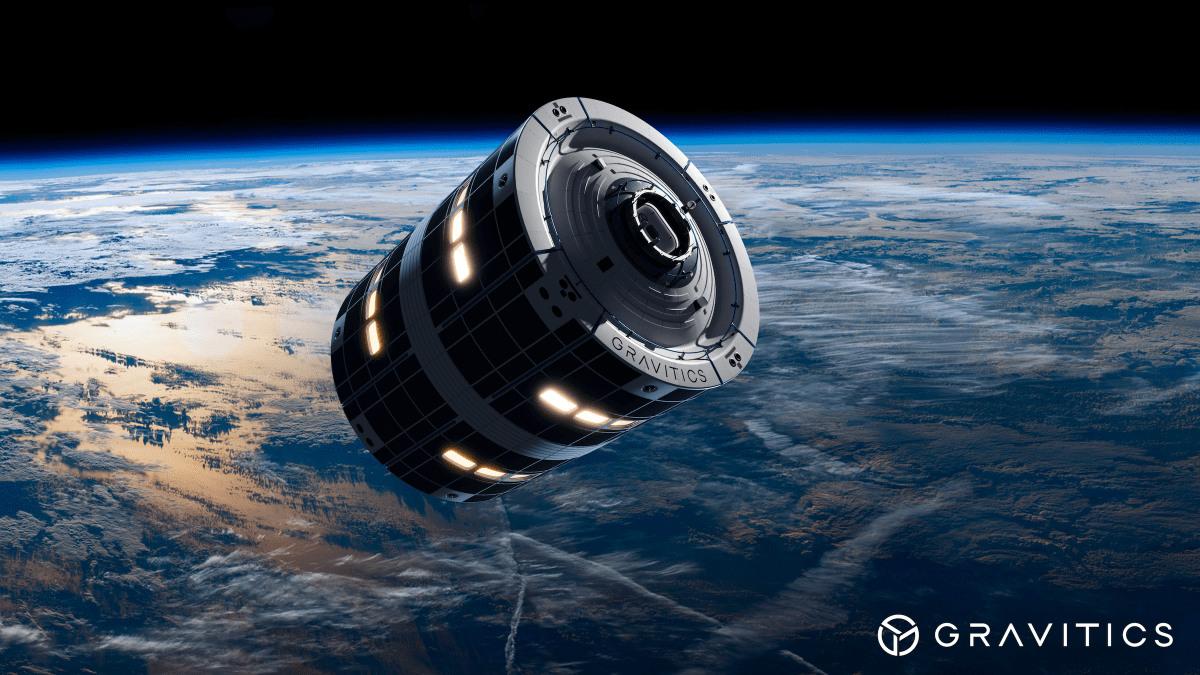

There’s one problem: The current testing regime for spacecraft focuses on payloads that are 4 meters wide or less. This poses a particular problem for companies such as gravitywhich is developing a line of space station modules ranging in diameter from 4 meters to 8 meters, with the hope that these modules will becomeIt is the building blocks for the next chapter in human space exploration.

So the company became proactive. Earlier this week, gravity It announced that it has signed a new agreement with NASA to address the shortage of testing and qualification methods for larger spacecraft. This series of qualification tests, which include thermal, vacuum, vibration and acoustic tests, are performed to ensure that the spacecraft can survive the harsh launch environment and the harsher space environment. Therefore, developing tests and standards for large spacecraft will be essential.

This is especially true for the large number of private companies looking to fill low Earth orbit with the next generation of private space stations. Thanks to the greater capacity of these upcoming rockets, these teams will almost certainly move away from NASA’s method of assembling the International Space Station — which took 10 years and more than 30 missions — and will instead launch fewer very large modules.

“We joke that we want to be ready to deliver modules from Stoke to Starship, from three meters to eight meters. We’re excited to work with groups like NASA to help ensure we can build those capabilities and take them to orbit,” said Colin Duggan, CEO of Gravitics. “Once the launch vehicles are ready and the customers are ready to receive them,” he said in a recent interview.

One example is vibration testing, which is designed to simulate the vibrations caused by launch and ensure that the spacecraft is still able to operate afterward. Smaller spacecraft are typically tested using shakers, but these devices are not designed to accommodate very large spacecraft or generate the forces needed to shake (or “excite”) a very large mass. The current testing model also makes some assumptions about portability, as companies often have to send their spacecraft to different test centers around the country – a task that becomes much more difficult when the vehicle in question is 8 meters wide.

Duggan was clear that this new agreement does not mean the process will result in a standard that NASA (and everyone else) will adhere to. This does not mean that NASA is particularly supportive of gravity. But at the very least, it will ensure the company has a NASA-approved path to launching its own products. If all goes well, and the two organizations jointly validate the new testing methods, it could help establish a standard.

“The capabilities increase when you start looking at large-scale space station modules, habitats, transportation, and other space infrastructure,” Mike DeRosa, Gravitics co-founder and chief marketing officer, said in an email. “Even things like space telescopes will get bigger and provide greater value to our civilization. These need to be certified for flight as well, and the process of creating successful methods and standards for that starts here with the work that Gravitics is doing.”